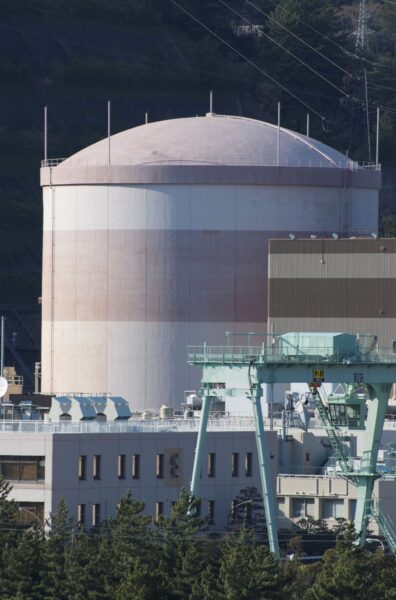

In an industry where the consequences of failure can have extremely far-reaching and long-lasting effects, maintaining safety is critical. To meet these safety demands, HARDLOCK® nuts have been implemented in over 17 nuclear power plants .

In this specific case, the double/ jam nut method was originally used to secure U-bolts and other piping assemblies within the nuclear reactor core. However, due to continuous operational loads and the large scale of the piping systems, daily retorquing was required to address loose nuts. U-bolt assemblies must achieve the correct bolt tension (preload) to function reliably. Excessive preload can damage the pipes, while insufficient preload increases the risk of rotational loosening.

The introduction of HARDLOCK® nuts effectively resolved the loosening issues associated with the jam nut method. The HARDLOCK® nut’s wedge-incorporated design creates a locking effect independent of preload. This allows for the safe application of lower preload levels, reducing the risk of pipe damage, while still preventing rotational loosening. As a result, maintenance and downtime due to loose U-bolt joints have been significantly reduced, and plant safety has been enhanced.