Features

Leveraging the power of the wedge principle used in ancient Japanese architecture, the HARDLOCK® Nut is the ultimate self-locking nut which completely integrates the nut and the bolt.

Self-locking effect recognized by the world

The HARDLOCK® Nut passes United States NAS (National Aerospace Standard) aviation standards

Torque and Axial Force control

Control the axial force with proper torque wherever used.

Reusable

Made of all metal with little few wear surfaces, sustains a powerful self-locking effect.

Easy and efficient

Can be easily installed with just one commercially available tool.

Economical

Reduced maintenance and labor add up to a significant savings in overall costs.

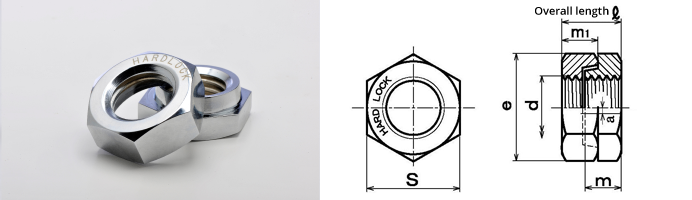

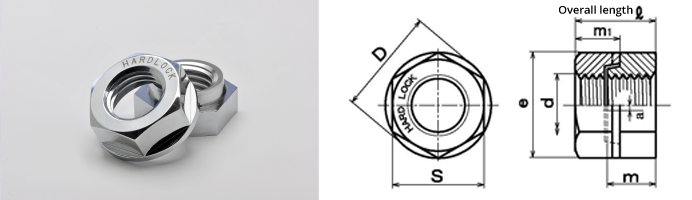

Self-locking design

The HARDLOCK® Nut has a structure that prevents looseness through the traditional Japanese principle of the wedge. To effectively utilize the wedge structure, two nuts are used: (1) a convex nut with an eccentrically formed boss, and (2) a perfectly circular concave nut. When these nuts are fastened together, the wedge principle mechanically creates a powerful locking effect transverse to the bolt shaft. This powerful anti-loosening effect achieved with the HARDLOCK® Nut wedge completely fuses the bolt and nut. Once locked with this powerful force, the HARDLOCK® Nut is not susceptible to impulsive forces or shocks.

Installation

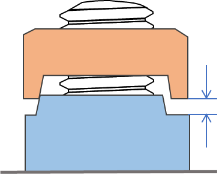

Use a tightening tool (spanner, torque wrench etc.) to tighten the Convex Nut to the appropriate torque for the application.

The convex nut has the same strength class as a regular hexagon nut and can therefore be tightened to its maximum limit.

Install the Concave nut onto the Convex nut manually by hand until it no longer turns (in other words, until prevailing torque is generated). Make sure that there is a gap of more than 1 thread pitch between the nuts.

If the gap is less than 1 pitch, there may be a chance that sufficient locking effect will not be produced so please refrain from using HARDLOCK® Nut with the bolt.

(The same conditions apply for reuse.)

Use a torque wrench to tighten the Concave nut with the recommended torque set by HARDLOCK Industry Co., Ltd.

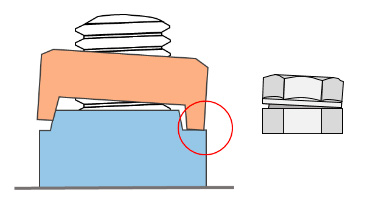

If it is difficult to manage the tightening torque of the Concave nut, please use “one-sided contact” as a guide for ensuring locking power.

When tightening the Concave nut on to the Convex nut, one side of the nuts will first come into contact, which gives an indication of sufficient locking effect (The Concave nut will slightly incline after the contact between the protrusion and the recess.). When one-sided contact is achieved, the tightening torque rapidly increases.

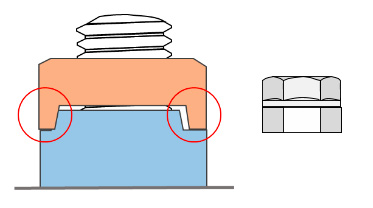

By applying additional torque , the nuts will come into full contact. This state produces the ultimate locking effect of the HARDLOCK® Nut, but further tightening may cause the breakage of bolt threads.

It is recommended to stop tightening the concave nut when the nuts come into full contact even though the applying torque is less than the maximum of recommended tightening torque.

Even after correctly tightening the Concave nut with the torque within the range of recommended tightening torque, there may remain a gap between the nuts due to the tolerance of bolt diameter.

Even in this condition, sufficient locking effect is secured but the Concave nut can be further tightened to come into one-sided contact or full contact even with more torque than the recommended torque to better ensure locking effect.

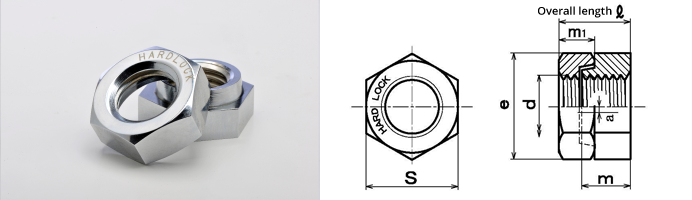

Dimension tables

Standard Rim

Basic Normal

Basic Thin